Services

Structure - Floors (correcting settlement)

.png)

One of our concepts is to "strengthen the building of the world."

It can be said that the structural technology of Japan, which is prone to earthquakes, is one of the most advanced in the world.

We also help to build and protect safe and strong buildings outside of Japan, based on the structural technology nurtured in Japan.

We have experience as a designer, supervisor, and advisor outside of Japan, so at least please feel free to contact us.

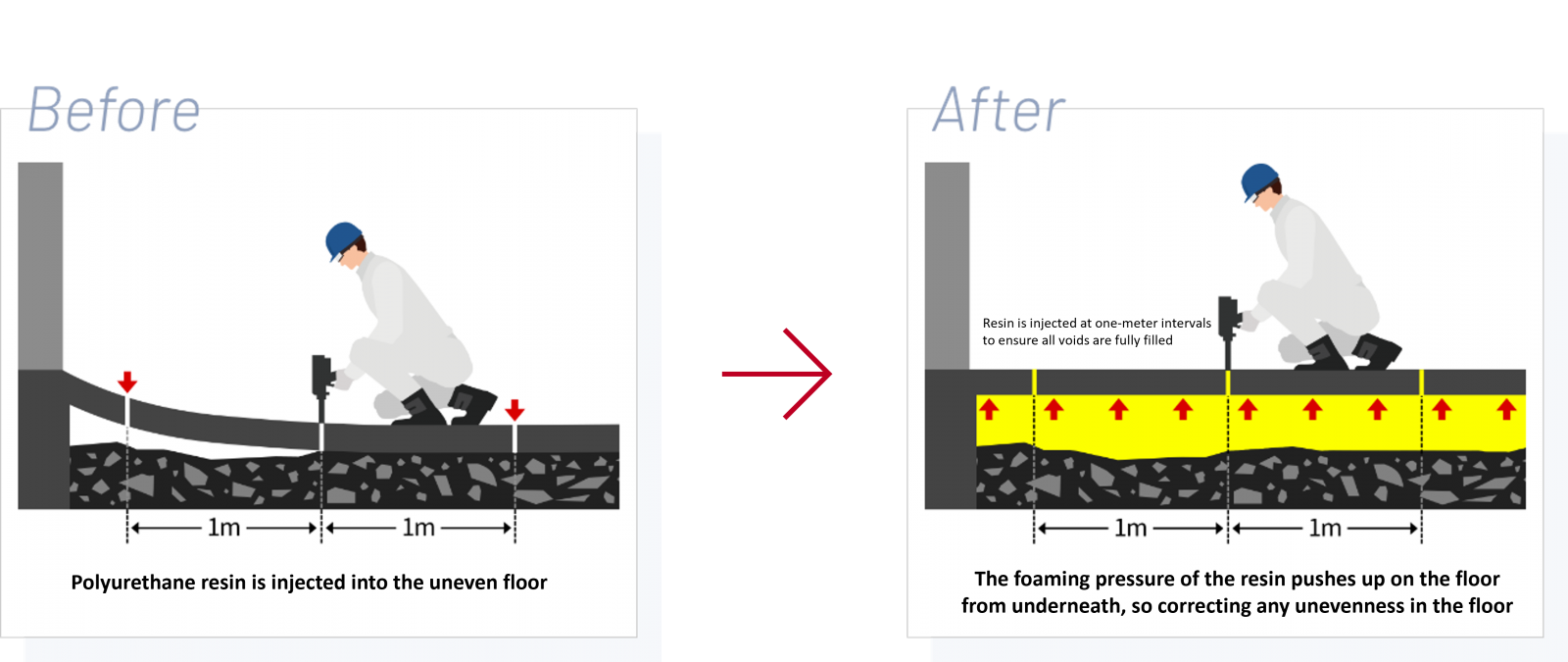

●We use rigid polyurethane foams to swiftly resolve various issues—such as being unable to level machinery, facing machinery with excessive vibrations, and having difficulty operating forklifts due—related to uneven floors in factories and warehouses due to earthquakes and settlement.

●In cases where existing concrete floors have settled or exhibit unevenness or voids, we open small holes measuring just 16mm across, and inject polyurethane resin, continually monitoring floor levels to an accuracy of one millimeter.

The polyurethane resin that has been injected under the floor rapidly foams and generates upward pressure. This consolidates the ground, improves its bearing capacity, and corrects unevenness in the concrete floor by pushing upward from below.

The same method can be used to fill underground voids, too.

●Polyurethane resin achieves its full strength in approximately 60 minutes. The resin pushes up on the floor with a maximum foam pressure of 10 tons per square meter; for this reason, corrections can be carried out without having to move heavy machinery or loads, and without having to interrupt factory or warehouse operations.

●Polyurethane resin has an effective range of approximately one meter; the UPCON Method therefore injects polyurethane resin at one-meter intervals to ensure that all underfloor voids are fully filled.

.png)